To Determine Young's Modulus of the Material of a Beam by Method of Vibration

1. Aim

2. Apparatus Used

- A metallic beam (rectangular cross-section)

- Two knife edges to support the beam

- A meter scale

- A screw gauge/micrometer

- A vernier caliper

- A stopwatch

- A small hammer

- Sand/iron filings

- Graph paper

- A weight hanger with weights (optional)

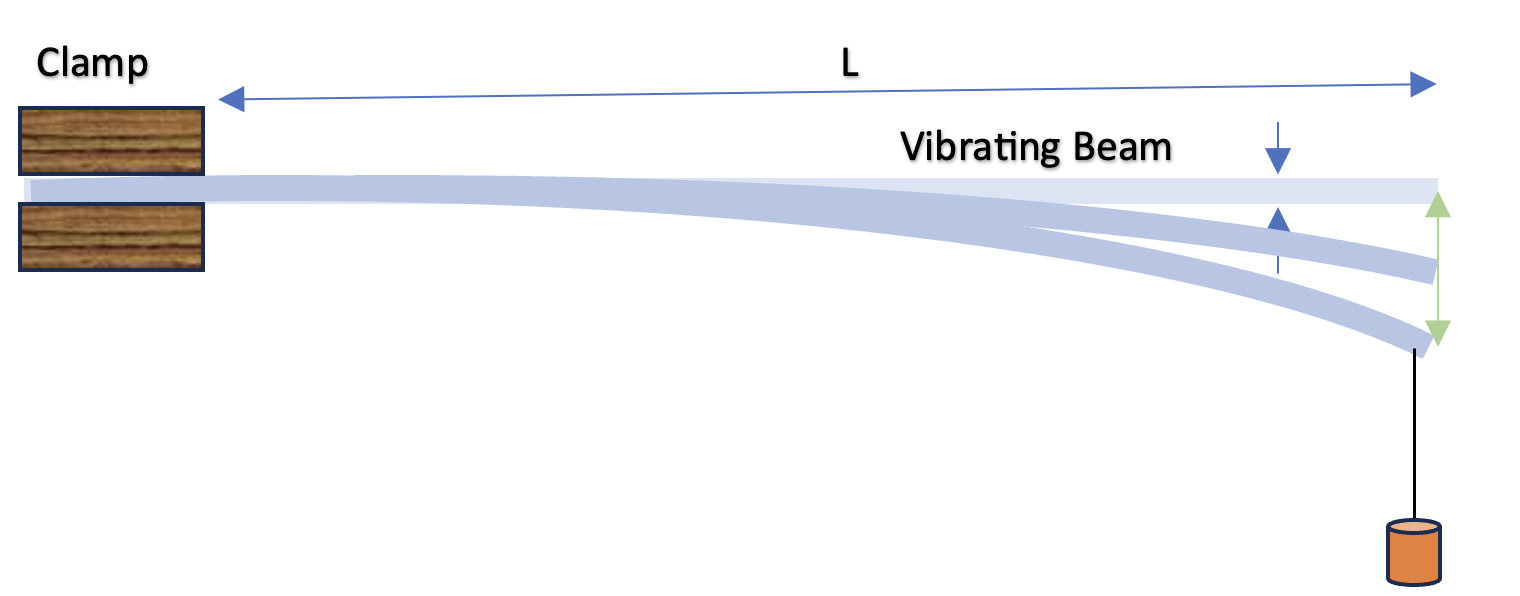

3. Diagram

Fig. 1: Experimental setup showing rectangular beam supported on two knife edges with measurement points for dimensions and vibration nodes representation

4. Theory

When a beam is set into transverse vibration, it vibrates with a natural frequency that depends on its dimensions, density, and elastic properties, particularly Young's modulus.

For a uniform beam of rectangular cross-section supported at both ends, the fundamental frequency of vibration is related to Young's modulus by the following relationship:

The beam vibrates according to the wave equation, and the natural frequency of vibration depends on:

- The length of the beam between supports (L)

- The moment of inertia of the cross-section (I)

- The mass per unit length (m)

- Young's modulus (E)

For a beam with both ends free to vibrate (simply supported):

The fundamental frequency is given by:

Where:

- f is the frequency of vibration

- L is the length of the beam between supports

- E is Young's modulus

- I is the moment of inertia of the cross-section

- ρ is the density of the beam material

- A is the cross-sectional area

For a rectangular beam:

- Moment of inertia I = bd³/12

- Area A = bd

- Where b is the width and d is the thickness of the beam

5. Formula

For a beam with rectangular cross-section, the formula for Young's modulus is:

Where:

- E = Young's modulus (N/m²)

- ρ = Density of the material (kg/m³)

- L = Length of the beam between supports (m)

- f = Fundamental frequency of vibration (Hz)

- d = Thickness/depth of the beam (m)

Alternatively, if the mass of the beam (M) is known:

Where:

- M = Mass of the beam (kg)

- b = Width of the beam (m)

6. Procedure

-

Measure the dimensions of the beam:

- Measure the length (L) of the beam using a meter scale.

- Measure the width (b) using vernier calipers at several positions and take the average.

- Measure the thickness (d) using a micrometer/screw gauge at several positions and take the average.

-

Determine the mass of the beam:

- Weigh the beam using a physical balance to determine its mass (M).

- Calculate the density (ρ) of the material if required, using ρ = M/(L×b×d).

-

Set up the experimental arrangement:

- Place the beam horizontally on two knife edges separated by a distance L.

- Ensure the beam is placed symmetrically on the knife edges.

-

Vibration measurement:

- Sprinkle some sand or iron filings lightly over the beam surface.

- Gently strike the beam at its center using a small hammer to set it into vibration.

- Observe the pattern formed by the sand/filings. These patterns (called Chladni patterns) show the nodal lines where vibration is minimal.

- Alternatively, observe the beam vibrations directly.

-

Frequency determination:

- Count the number of vibrations in a given time using the stopwatch.

- Repeat this several times and take the average.

- Calculate the frequency (f) by dividing the number of vibrations by the time taken.

-

Alternative method for frequency determination:

- Apply small weights at the center of the beam and measure the time period for different loads.

- Plot a graph between the time period and the square root of the load.

- Extrapolate to find the natural frequency of the unloaded beam.

7. Observation Table

A. Dimensional Measurements

| Parameter | Measurement 1 | Measurement 2 | Measurement 3 | Average Value |

|---|---|---|---|---|

| Length (L) | ... m | ... m | ... m | ... m |

| Width (b) | ... m | ... m | ... m | ... m |

| Thickness (d) | ... m | ... m | ... m | ... m |

| Mass (M) | ... kg | ... kg | ... kg | ... kg |

B. Frequency Determination

| Trial | Number of Vibrations | Time Taken (s) | Frequency (Hz) |

|---|---|---|---|

| 1 | ... | ... | ... |

| 2 | ... | ... | ... |

| 3 | ... | ... | ... |

| 4 | ... | ... | ... |

| 5 | ... | ... | ... |

| Average | ... |

C. Alternative Method (if used)

| Load (kg) | Time Period (s) | √Load |

|---|---|---|

| 0 | ... | 0 |

| 0.1 | ... | ... |

| 0.2 | ... | ... |

| 0.3 | ... | ... |

| 0.4 | ... | ... |

| 0.5 | ... | ... |

8. Calculations

-

Calculate the average dimensions:

- Average length (L) = ... m

- Average width (b) = ... m

- Average thickness (d) = ... m

- Mass (M) = ... kg

- Density (ρ) = M/(L×b×d) = ... kg/m³

-

Calculate the average frequency:

- Average frequency (f) = ... Hz

-

Calculate Young's modulus:

Using the formula:

\[E = \frac{48\pi^2 \rho L^4 f^2}{d^2}\]Substituting values:

E = 48 × π² × (density) × (length)⁴ × (frequency)² / (thickness)²

E = 48 × (3.14159)² × ... × ...⁴ × ...² / ...²

E = ... N/m²

-

Error calculation (optional):

- Calculate the percentage error from standard value (if known)

- Error = [(Experimental value - Standard value) / Standard value] × 100%

9. Result

The Young's modulus of elasticity of the material of the given beam determined by the method of vibration is ... × 10⁹ N/m² or ... GPa.

10. Precautions

- Ensure the beam has a uniform cross-section throughout its length.

- The supports (knife edges) should be sharp and rigid.

- The beam should be placed symmetrically on the supports.

- Measure the dimensions of the beam carefully at multiple positions.

- Strike the beam gently to produce small amplitude vibrations.

- Ensure the beam is clean and free from dirt or grease.

- Take multiple readings and use average values for accurate results.

- The beam should be free from initial stress and strain.

- The beam should not be too heavy or too light for the setup.

- Avoid any external vibrations that might interfere with the experiment.

- Ensure the beam is perfectly horizontal when placed on the supports.

- The laboratory temperature should be noted as it affects the Young's modulus.